Inline Excellence.

Perfection all down the line.

Measurably more efficient

We represent technology that redefines excellence. With high-precision and smart measurement technology that integrates seamlessly into your production lines. And enables you to improve quality measurably and in real time.

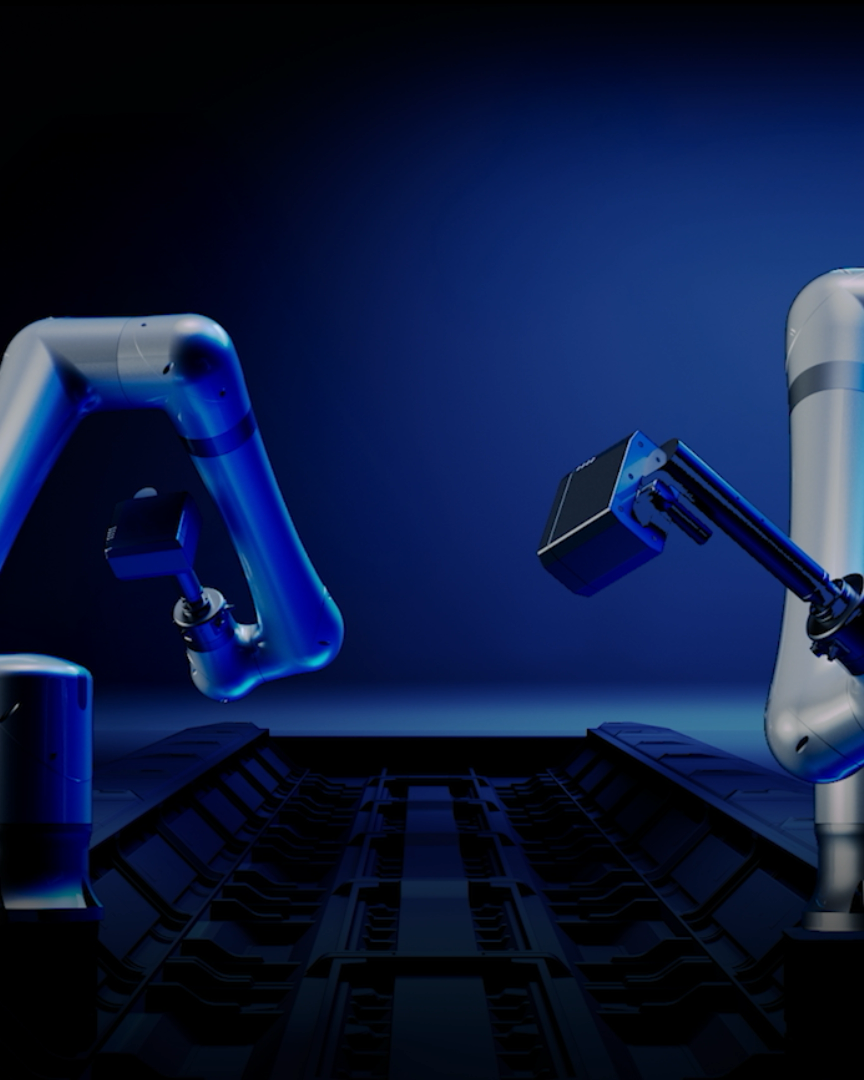

AICell MMC: Proven technology – reimagined

Our measurement technology has proven itself in automotive production for years. Now it is also being made available to new customer groups and industries – as the mobile AICell MMC: whether for mechanical engineering, aerospace or small and medium-sized companies – simply for anyone who wants to benefit from flexible, efficient and ready-to-use measurement technology.

“NEWSTON, we have a problem.”

“Problem? We have NEWSTON!”

Precision meets process understanding – you can rely on our team with its many years of experience. We advise with passion, openly and honestly. That's why customers around the world trust us. Because they know: If it can be done, NEWSTON makes it possible.

Automotive Industry

Challenge: High cycle rate, increasing number of variants, zero-defect strategy

Benefit: Inline measurement technology ensures 100% control at maximum speed - precise, documented and seamlessly integrated into your production line.

Aerospace Industry

Challenge: Complex components, extremely tight tolerances, safety certificates

Benefit: Non-contact 3D measurement technology enables high-precision inspections - for maximum safety, conformity to standards and certifiable quality.

Supplier Industry

Challenge: Cost pressure, high part variance, traceability to OEMs

Benefit: Automated systems inspect efficiently and provide reliable measurement data - for consistently high quality and reliable customer satisfaction.

Commercial vehicle industry

Challenge: Large component dimensions, robust application requirements

Benefit: Our measurement technology solutions guarantee precise testing, even for large structures - directly in the production process and without wasting time.